Stanford scientists invent ultrafast way to manufacture perovskite solar modules

26. 11. 2020 | Stanford University | www.stanford.edu

Most solar cells today are made with refined silicon that turns sunlight into clean electricity. Unfortunately, the process of refining silicon is far from clean, requiring vast amounts of energy from carbon-emitting power plants.

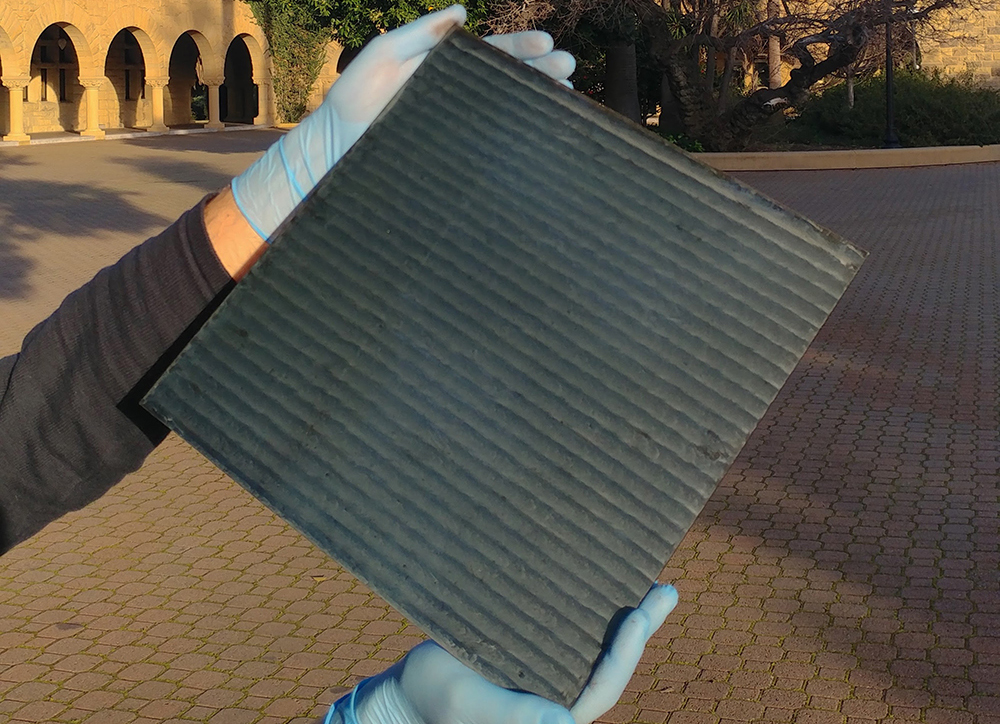

For a greener alternative to silicon, researchers have focused on thin-film perovskites – low-cost, flexible solar cells that can be produced with minimal energy and virtually no CO2 emissions. While perovskite solar cells are promising, significant challenges need to be addressed before they can become commonplace, not least of which is their inherent instability, which makes manufacturing them at scale difficult.

In a new study, published in the Nov. 25 issue of the journal Joule, researchers from Stanford University demonstrate an ultrafast way to produce stable perovskite cells and assemble them into solar modules that could power devices, buildings and even the electricity grid. To address the challenge of large-scale production, the team deployed a patented technology they recently invented called rapid-spray plasma processing. This technology uses a robotic device with two nozzles to quickly produce thin films of perovskite. One nozzle spray-coats a liquid solution of perovskite chemical precursors onto a pane of glass, while the other releases a burst of highly reactive ionized gas known as plasma.

Read more at Stanford University

Image Credit: Nick Rolston

-jk-