You can now 3D print objects made of glass

21. 4. 2017 | The Verge | www.theverge.com

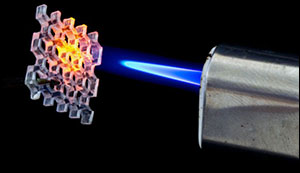

Scientists in Germany have 3D printed very intricate tiny objects using glass. In the future, the technique could be used to 3D print things like complex lenses, filters, and even ornaments that generally need highly skilled artisans to make.

The researchers used a type of “liquid glass” to make complex shapes that are smooth, transparent, and have a very high resolution, according to a study published recently in Nature. More importantly, the glass objects were created using standard and commonly used 3D printers.

The “liquid glass” is a glass powder embedded into a liquid polymer. Here’s how it works: a standard 3D printer uses the liquid glass to print an object. The object is then processed in a high-temperature oven where the glass particles fuse together, becoming transparent. The technique was used to make objects like a castle gate, a pretzel, and a honeycomb structure that are a few millimeters in size, and have features as small as a few tens of micrometers. The objects could also withstand temperatures as high as 1,472 degrees Fahrenheit.

Read more at The Verge

Image Credit: NeptunLab/KIT

-jk-