UCLA researchers turn carbon dioxide into sustainable concrete

16. 3. 2016 | UCLA | newsroom.ucla.edu

Imagine a world with little or no concrete. Would that even be possible? After all, concrete is everywhere — on our roads, our driveways, in our homes, bridges and buildings. For the past 200 years, it’s been the very foundation of much of our planet.

But the production of cement, which when mixed with water forms the binding agent in concrete, is also one of the biggest contributors to greenhouse gas emissions. In fact, about 5 percent of the planet’s greenhouse gas emissions comes from concrete. An even larger source of carbon dioxide emissions is flue gas emitted from smokestacks at power plants around the world. Carbon emissions from those plants are the largest source of harmful global greenhouse gas in the world.

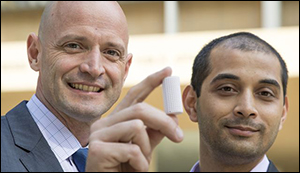

A team of interdisciplinary researchers at UCLA has been working on a unique solution that may help eliminate these sources of greenhouse gases. Their plan would be to create a closed-loop process: capturing carbon from power plant smokestacks and using it to create a new building material — CO2NCRETE — that would be fabricated using 3D printers. That’s “upcycling.” Thus far, the new construction material has been produced only at a lab scale, using 3-D printers to shape it into tiny cones.

Read more at UCLA

Image Credit: UCLA

-jk-