UCLA engineer develops 3D printer that can create complex biological tissues

24. 5. 2018 | UCLA | www.ucla.edu

UCLA bioengineer has developed a technique that uses a specially adapted 3D printer to build therapeutic biomaterials from multiple materials. The advance could be a step toward on-demand printing of complex artificial tissues for use in transplants and other surgeries.

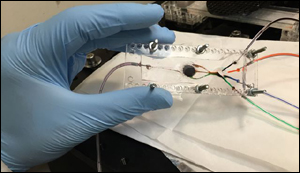

The technique uses a light-based process called stereolithography, and it takes advantage of a customized 3D printer that has two key components. The first is a custom-built microfluidic chip — a small, flat platform similar in size to a computer chip — with multiple inlets that each “prints” a different material. The other component is a digital micromirror, an array of more than a million tiny mirrors that each moves independently.

The researchers used different types of hydrogels – materials that, after passing through the printer, form scaffolds for tissue to grow into. The micromirrors direct light onto the printing surface, and the illuminated areas indicate the outline of the 3D object that’s being printed. The light also triggers molecular bonds to form in the materials, which causes the gels to firm into solid material. As the 3D object is printed, the mirror array changes the light pattern to indicate the shape of each new layer.

Read more at UCLA

Image Credit: Amir Miri

-jk-