Transparent silver for flexible displays, touch screens, metamaterials

22. 3. 2017 | University of Michigan | ns.umich.edu

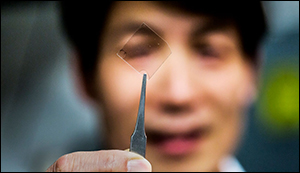

The thinnest, smoothest layer of silver that can survive air exposure has been laid down at the University of Michigan, and it could change the way touchscreens and flat or flexible displays are made.

By combining the silver with a little bit of aluminum, the U-M researchers found that it was possible to produce exceptionally thin, smooth layers of silver that are resistant to tarnishing. They applied an anti-reflective coating to make one thin metal layer up to 92.4 percent transparent.

The team showed that the silver coating could guide light about 10 times as far as other metal waveguides—a property that could make it useful for faster computing. And they layered the silver films into a metamaterial hyperlens that could be used to create dense patterns with feature sizes a fraction of what is possible with ordinary ultraviolet methods, on silicon chips, for instance.

By adding about 6 percent aluminum, the researchers coaxed the metal into a film of less than half that thickness—seven nanometers. What's more, when they exposed it to air, it didn't immediately tarnish as pure silver films do. After several months, the film maintained its conductive properties and transparency.

Read more at University of Michigan

Image Credit: Joseph Xu/Michigan Engineering

-jk-