Toward all-solid lithium batteries

6. 2. 2017 | MIT News | news.mit.edu

Most batteries are composed of two solid, electrochemically active layers called electrodes, separated by a polymer membrane infused with a liquid or gel electrolyte. But recent research has explored the possibility of all-solid-state batteries, in which the liquid (and potentially flammable) electrolyte would be replaced by a solid electrolyte, which could enhance the batteries’ energy density and safety.

Lithium-ion batteries have provided a lightweight energy-storage solution that has enabled many of today’s high-tech devices, from smartphones to electric cars. But substituting the conventional liquid electrolyte with a solid electrolyte in such batteries could have significant advantages. Such all-solid-state lithium-ion batteries could provide even greater energy storage ability, pound for pound, at the battery pack level. They may also virtually eliminate the risk of tiny, fingerlike metallic projections called dendrites that can grow through the electrolyte layer and lead to short-circuits.

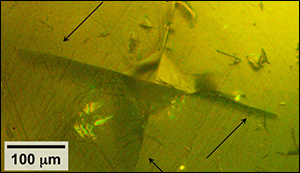

Until now, though, the sulfide’s extreme sensitivity to normal lab air has posed a challenge to measuring mechanical properties including its fracture toughness. To circumvent this problem, members of the research team conducted the mechanical testing in a bath of mineral oil, protecting the sample from any chemical interactions with air or moisture. Using that technique, they were able to obtain detailed measurements of the mechanical properties of the lithium-conducting sulfide, which is considered a promising candidate for electrolytes in all-solid-state batteries.

Read more at MIT News

Image Credit: MIT News

-jk-