Tough material for next generation of powerful engines

31. 3. 2017 | Rice University | news.rice.edu

To stand up to the heat and pressure of next-generation rocket engines, the composite fibers used to make them should be fuzzy.

The Rice University laboratory of materials scientists, in collaboration with NASA, have developed “fuzzy fibers” of silicon carbide that act like Velcro and stand up to the punishment that materials experience in aerospace applications.

The fibers strengthen composites used in advanced rocket engines that have to withstand temperatures up to 1,600 degrees Celsius (2,912 degrees Fahrenheit). Ceramic composites in rockets now being developed use silicon carbide fibers to strengthen the material, but they can crack or become brittle when exposed to oxygen.

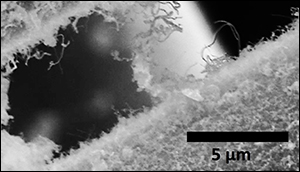

The Rice lab embedded silicon carbide nanotubes and nanowires into the surface of NASA’s fibers. The exposed parts of the fibers are curly and act like the hooks and loops that make Velcro so valuable – but on the nanoscale.

Read more at Rice University

Image Credit: Ajayan Research Group

-jk-