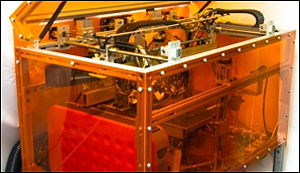

This 3D Printer Can Print 10 Materials Simultaneously

28. 8. 2015 | MIT News | news.mit.edu

3-D printing is great, assuming you're printing one material for one purpose, and that you’re fine with a few do-overs. But the technology is still far behind in reliably producing a variety of useful objects, with no assembly required, at a moderate cost.

In recent years, companies have been working to tackle some of these challenges with “multi-material” 3-D printers that can fabricate many different functional items. Such printers, however, have traditionally been limited to three materials at a time, can cost as much as $250,000 each, and still require a fair amount of human intervention.

But this week, researchers at MIT’s Computer Science and Artificial Intelligence Laboratory (CSAIL) say that they’ve found a way to make a better, cheaper, more user-friendly printer. In a paper accepted at the SIGGRAPH computer-graphics conference, a CSAIL team presented a 3-D printer that can print an unprecedented 10 different materials at once by using 3-D-scanning techniques that save time, energy, and money.

Delivering resolution at 40 microns - or less than half the width of a human hair - the “MultiFab” system is the first 3-D printer to use 3-D-scanning techniques from machine vision, which offers two key advantages in accuracy and convenience over traditional 3-D printing.

Read more at MIT News

Image Credit: Tom Buehler/CSAIL

-jk-