Seabed-Mining Robots Will Dig for Gold in Hydrothermal Vents

23. 12. 2015 | IEEE Spectrum | spectrum.ieee.com

For decades, futurists have predicted that commercial miners would one day tap the unimaginable mineral wealth of the world’s ocean floor. Soon, that subsea gold rush could finally begin.

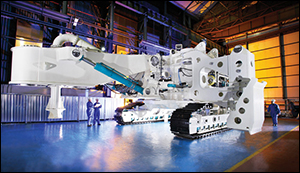

The world’s first deep-sea mining robots are poised to rip into rich deposits of copper, gold, and silver 1,600 meters down at the bottom of the Bismarck Sea, near Papua New Guinea. The massive machines, which are to be tested sometime in 2016, are part of a high-stakes gamble for the Toronto-based mining company Nautilus Minerals.

The mining robots were built for Nautilus by Soil Machine Dynamics, based in the United Kingdom, which supplies construction equipment for laying undersea cables, servicing offshore oil platforms, and other heavy-duty deep-sea jobs. The main robots are a pair of tractor-trailer-size excavators. One uses 4-meter-wide counterrotating heads studded with tungsten carbide picks to chew through the metal-rich chimneys that form around superhot water spewing from sulfurous vents in the seafloor. Its partner adds brute strength, using a studded drum that is 2.5 meters in diameter and 4 meters wide to pulverize rock walls.

Dredge pumps built into these machines will push the smashed ore back to a central pile on the seafloor, where a third Nautilus robot will feed a slurry of crushed rock and water up a pipe dangling from the production vessel. There the water will be wrung out from the ore, which will be loaded on another ship and carried to China for processing.

Read more at IEEE Spectrum

Image Credit: Nautilus Minerals

-jk-