Scientists develop safer, more durable lithium-ion battery that can operate under extreme conditions

13. 11. 2017 | Johns Hopkins University | hub.jhu.edu

Lithium-ion batteries have become the energy storage method of choice for consumer electronics and military and aerospace systems alike. But potential safety hazards associated with the organic electrolytes that are used in Li-ion battery cells remain an ongoing concern.

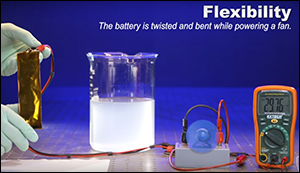

Team of scientists at the Johns Hopkins Applied Physics Laboratory has partnered with researchers from the University of Maryland and the Army Research Laboratory to develop a new type of flexible lithium-ion battery that is not hazardous and can operate under extreme conditions including cutting, submersion, and ballistic impact.

The team operated their flexible Li-ion battery in open air with minimal packaging, using only some electronically insulating, heat-resistant tape to keep it in place. In their demonstration, the battery powered a significant motor load without any safety concerns. To demonstrate the full safety potential, the team performed a series of tests while the battery was in operation, including cutting it, immersing it in sea water, and subjecting it to ballistic testing at an APL facility.

Read more at Johns Hopkins University

Image Credit: Johns Hopkins University

-jk-