Polymer additive could revolutionize plastics recycling

24. 2. 2017 | Cornell University | www.news.cornell.edu

What percentage of the 78 million tons of plastic used annually for packaging actually gets recycled and reused in a similar way? The answer is just 2 percent. Sadly, nearly a third is leaked into the environment, around 14 percent is used in incineration and/or energy recovery, and a whopping 40 percent winds up in landfills.

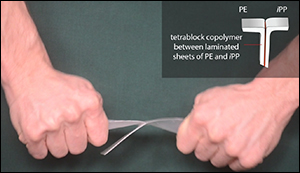

One of the problems: Polyethylene (PE) and polypropylene (PP), which account for two-thirds of the world’s plastics, have different chemical structures and thus cannot be repurposed together. That could change with a discovery out lab of Cornell University. Geoffrey Coates and his group have collaborated with a group from the University of Minnesota to develop a multiblock polymer that, when added in small measure to a mix of the two otherwise incompatible materials, create a new and mechanically tough polymer.

In their test, two strips of plastic were welded together using different multi-block polymers as adhesives, then mechanically pulled apart. While the welds made with diblock polymers failed relatively quickly, the weld made of the group’s tetrablock additive held so well that the plastic strips broke instead.

Read more at Cornell University

Image Credit: Cornell University

-jk-