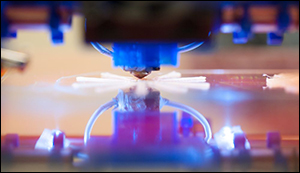

Making new functional polymers for 3-D printers

19. 10. 2016 | Phys.org | www.phys.org

Chemical engineers at the University of Melbourne have found a way to 3-D print smart polymers (or plastics) that can perform a function, in a way that is cheaper, cleaner and more accessible than ever before.

These smart and functional polymers that are being produced are not the inert objects, we are used to associating with 3-D printed objects, but are built to undertake a chemical reaction, so that they can perform a function in a particular environment.

The project is challenging from both the synthesis and production side of creating the material, to the printing side, ensuring that the material has the right shape and complex properties to carry out its function, as well as being 3-D printable.

A filament must first be produced, which can be fed into the printer, melted and 3-D printed. The second is a catalytic device that can remove an environmental pollutant from water. In the experiment conducted, the 3-D printed polymer catalyst is placed in a yellow (contaminated) solution, which turns clear over time, when the toxic substance has been neutralised.

Read more at Phys.org

Image Credit: University of Melbourne

-jk-