Lasers etch a ‘perfect’ solar energy absorber

5. 2. 2020 | University of Rochester | www.rochester.edu

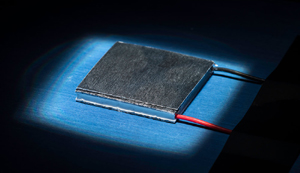

The University of Rochester research lab that recently used lasers to create unsinkable metallic structures has now demonstrated how the same technology could be used to create highly efficient solar power generators.

Research, published in a Light: Science & Applications, describes using powerful femto-second laser pulses to etch metal surfaces with nanoscale structures that selectively absorb light only at the solar wavelengths, but not elsewhere. A regular metal surface is shiny and highly reflective. Years ago, the researchers developed a black metal technology that turned shiny metals pitch black. “But to make a perfect solar absorber we need more than a black metal and the result is this selective absorber.”

The researchers experimented with aluminum, copper, steel, and tungsten, and found that tungsten, commonly used as a thermal solar absorber, had the highest solar absorption efficiency when treated with the new nanoscale structures. This improved the efficiency of thermal electrical generation by 130 percent compared to untreated tungsten.

Read more at University of Rochester

Image Credit: J. Adam Fenster

-jk-