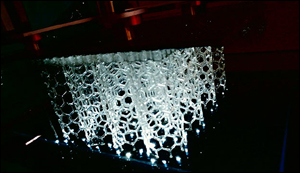

Highest-throughput 3D printer is future of manufacturing

18. 10. 2019 | Northwestern University | www.northwestern.edu

Northwestern University researchers have developed a new, futuristic 3D printer that is so big and so fast it can print an object the size of an adult human in just a couple of hours.

Called HARP (high-area rapid printing), the new technology enables a record-breaking throughput that can manufacture products on demand. Over the last 30 years, most efforts in 3D printing have been aimed at pushing the limits of legacy technologies. Often, the pursuit of larger parts has come at the cost of speed, throughput and resolution. With HARP technology, this compromise is unnecessary, enabling it to compete with both the resolution and throughput of traditional manufacturing techniques.

The prototype HARP technology is 13-feet tall with a 2.5 square-foot print bed and can print about half a yard in an hour — a record throughput for the 3D printing field. This means it can print single, large parts or many different small parts at once.

Read more at Northwestern University

Image Credit: Northwestern University

-jk-