Graphene-based wearable e-textiles move closer to commercial production

20. 12. 2017 | Phys.org | www.phys.org

The market for e-textile clothing is forecasted to reach $5 billion by 2027, according to the market research firm IDTechEX. And while graphene is expected to be one of the most prominent materials in wearable e-textiles, currently there is no good way to manufacture graphene-based e-textiles on an industrial scale.

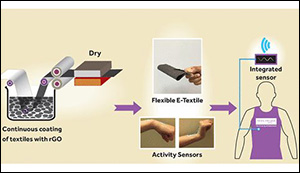

To address this problem, a team of researchers led by Professor Kostya S. Novoselov at The University of Manchester have developed a scalable process to manufacture graphene-based wearable e-textiles on an industrial scale. As they write in their paper published in a recent issue of ACS Nano, the method could allow graphene e-textiles to be manufactured at commercial production rates of 150 meters per minute.

In the new method, the team has reversed the previous process of coating textiles with graphene-based materials. Traditionally, the textiles are first coated with graphene oxide, and then the graphene oxide is reduced to its functional form of reduced graphene oxide. Instead, here the researchers first reduced the graphene oxide in solution, and then coated the textiles with the reduced form.

Read more at Phys.org

Image Credit: American Chemical Society

-jk-