Future electronic components to be printed like newspapers

20. 7. 2018 | Purdue University | www.purdue.edu

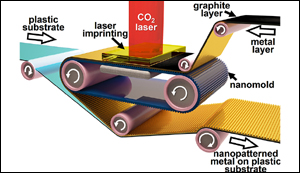

Purdue researchers have developed a new technique that prints metals like newspapers, making them smoother and more flexible for better current flow throughout a metallic circuit. Future ultrafast devices also will require much smaller metal components, which calls for a higher resolution to make them at these nanoscale sizes.

The low-cost process, developed by Purdue University researchers, combines tools already used in industry for manufacturing metals on a large scale, but uses the speed and precision of roll-to-roll newspaper printing to remove a couple of fabrication barriers in making electronics faster than they are today.

The fabrication method, called roll-to-roll laser-induced superplasticity, uses a rolling stamp like the ones used to print newspapers at high speed. The technique can induce, for a brief period of time, “superelastic” behavior to different metals by applying high-energy laser shots, which enables the metal to flow into the nanoscale features of the rolling stamp – circumventing the formability limit.

Read more at Purdue University

Image Credit: Purdue University/Ramses Martinez

-jk-