3D printing enables the smallest complex micro-objectives

12. 8. 2016 | University of Stuttgart | www.uni-stuttgart.de

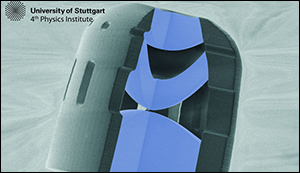

3D printing revolutionized the manufacturing of complex shapes in the last few years. Using additive depositing of materials, where individual dots or lines are written sequentially, even the most complex devices could be realized fast and easy. Researchers at University of Stuttgart in Germany have used an ultrashort laser pulses in combination with optical photoresist to create optical lenses which are hardly larger than a human hair.

The femtosecond laser, with pulse durations smaller than 100 femtoseconds, is being focused in a microscope into liquid photoresist which rests on a glass substrate or an optical fiber. Two photons of the red laser beam with a wavelength of 785 nm are being absorbed simultaneously in the focus and expose the photoresist. This crosslinks the polymer and hardens it. The laser beam is directed with a scanner or by moving the substrate over the substrate. After exposure, the unexposed photoresist is washed away with a solvent. Only the hardened transparent polymer remains and forms the optical element.

Using this method, optical free form surfaces can be created with sub-micrometer accuracy. The precision of the 3D laser writing allows not only for construction of common spherical lenses, but also the more ideal surfaces such as paraboloids or aspheres of higher order are possible. Particularly optical lens systems with two or more lenses can be realized for the first time with this method. This opens the door to aberration correction and microoptical imaging systems with unprecedented quality.

Read more at University of Stuttgart

Image Credit: University of Stuttgart

-jk-