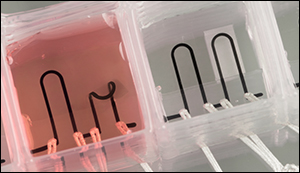

3D-printed heart-on-a-chip with integrated sensors

24. 10. 2016 | Harvard University | www.seas.harvard.edu

Harvard University researchers have made the first entirely 3D-printed organ-on-a-chip with integrated sensing. Built by a fully automated, digital manufacturing procedure, the 3D-printed heart-on-a-chip can be quickly fabricated and customized, allowing researchers to easily collect reliable data for short-term and long-term studies.

This new approach to manufacturing may one day allow researchers to rapidly design organs-on-chips, also known as microphysiological systems, that match the properties of a specific disease or even an individual patient’s cells.

Organs-on-chips mimic the structure and function of native tissue and have emerged as a promising alternative to traditional animal testing. Harvard researchers have developed microphysiological systems that mimic the microarchitecture and functions of lungs, hearts, tongues and intestines.

However, the fabrication and data collection process for organs-on-chips is expensive and laborious. Currently, these devices are built in clean rooms using a complex, multi-step lithographic process and collecting data requires microscopy or high-speed cameras. The researchers developed six different inks that integrated soft strain sensors within the micro-architecture of the tissue. In a single, continuous procedure, the team 3D printed those materials into a cardiac microphysiological device — a heart on a chip — with integrated sensors.

Read more at Harvard University

Image Credit: Harvard University

-jk-