3D-printed ‘bionic skin’ could give robots the sense of touch

12. 5. 2017 | University of Minnesota | twin-cities.umn.edu

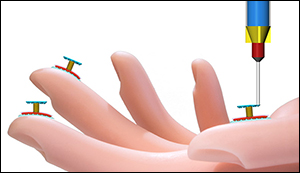

Engineering researchers at the University of Minnesota have developed a revolutionary process for 3D printing stretchable electronic sensory devices that could give robots the ability to feel their environment. The discovery is also a major step forward in printing electronics on real human skin.

“This stretchable electronic fabric we developed has many practical uses,” said Michael McAlpine, a University of Minnesota mechanical engineering associate professor and lead researcher on the study. “Putting this type of ‘bionic skin‘ on surgical robots would give surgeons the ability to actually feel during minimally invasive surgeries, which would make surgery easier instead of just using cameras like they do now. These sensors could also make it easier for other robots to walk and interact with their environment.”

McAlpine and his team made the unique sensing fabric with a one-of-a kind 3D printer they built in the lab. The multifunctional printer has four nozzles to print the various specialized “inks” that make up the layers of the device—a base layer of silicone, top and bottom electrodes made of a conducting ink, a coil-shaped pressure sensor, and a sacrificial layer that holds the top layer in place while it sets. The supporting sacrificial layer is later washed away in the final manufacturing process.

Read more at University of Minnesota

Image Credit: Wiley-VCH Verlag GmbH & Co. KGaA

-jk-