3-D printing with cellulose

6. 3. 2017 | MIT News | news.mit.edu

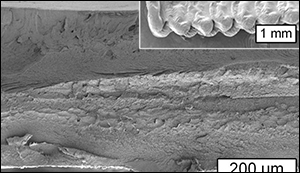

For centuries, cellulose has formed the basis of the world's most abundantly printed-on material: paper. Now, thanks to new research at MIT, it may also become an abundant material to print with—potentially providing a renewable, biodegradable alternative to the polymers currently used in 3-D printing materials.

The MIT team chose to work with cellulose acetate—a material that is easily made from cellulose and is already widely produced and readily available. Essentially, the number of hydrogen bonds in this material has been reduced by the acetate groups. Cellulose acetate can be dissolved in acetone and extruded through a nozzle. As the acetone quickly evaporates, the cellulose acetate solidifies in place. A subsequent optional treatment replaces the acetate groups and increases the strength of the printed parts.

To demonstrate the chemical versatility of the production process, researchers added an extra dimension to the innovation. By adding a small amount of antimicrobial dye to the cellulose acetate ink, they 3-D-printed a pair of surgical tweezers with antimicrobial functionality.

Read more at MIT News

Image Credit: MIT News

-jk-