New Teco building shows a sample solution for energy-efficient buildings

25. 5. 2018 | Teco a.s. | www.tecomat.com

We have presented a sample concept of extermely energy-efficient building, equipped by our control system Tecomat Foxtrot. This concept is our own manufacturing and administative building in Kolin/Czech Republic. Our building has become the training center for automation applicating companies from all over the world, where they can learn the latest automation know-how on a real project.

The new Teco a. s. building is built in the industrial area on the eastern edge

of the town of Kolin.

In 2017 we have built our new Teco building on a green field in the Šťáralka industrial zone, on our own land, for our money and without any subsidies. We managed to do that in total of eight months. After two years of designing, we have chosen a construction company Navláčil from Zlín. Excavators took their first dirt bites at the end of February. The final building permit inspection took place at the beginning of November and the relocation of the entire company took three weeks, plus one-week production interruption. That is all we have to say about the timeframe of the construction project and subsequent logistics operations which allowed us to start the next quarter of the existence of Teco a.s. in our new building fully equipped with new technologies.

Fig. New Teco a.s. building in Kolin. View from the south; source: Teco, a. s

Architecture and structural design

The pure purpose oriented two-storey building was divided by the architect Irena Schusterová into four parts - the manufacturing section and warehouses, all located at the ground floor towards the right side and the training centre, sales and purchasing departments and dining room with meal serving section on the left. The development and administrative sections are on the first floor.

These four operating sections, which may be separated and individually closed, are connected by a spacious communication centre whose façade is the visual dominant feature of the entire building. Inspired by the two-dimensional logo of the company using the typical motif of a periodic signal provided a third dimension which passes through the entire width of the building, from the north to the south façade.

The ground plan of the main building represents a rectangle 21 m wide and 60 m long, the longer side facing the east-west direction. The two uneven floors of the building are built above this rectangle. Flat roofs cover the entire building. The simple concept of the two-storey unit is disrupted at approximately one third of the building’ length by the “indentation” representing the Teco, a.s. logo with a glass-fitted staircase, to which partially roofed terraces are connected. This highlights the main entrance to the building. The “indentation” in the mass of the building follows a line of striped windows equipped with outdoor blinds that run around the entire perimeter of the building and provide natural light and ventilation for all rooms in the building.

The entire building is wheelchair-accessible. In addition to the staircase, the first and second floor may also be accessed by an electric lifting platform.

The main entrance to the building leads to the access road which runs around the entire facility offering 50 parking spaces and all the way to the rear entrances which lead to the material receiving section, ,goods shipping section and meal receiving area which are served in the dining room. The building rests on reinforced concrete structures filled with panel system made of light insulation materials. Sheathing around the building is made of PUR panels. The inner facings and partitions are made of plasterboards fitted with plastic windows equipped with triple glass panels. The inner and entrance doors are made of aluminum and are also fitted with glass panels. No bright colors have been used to draw unnecessary attention. The building color pattern has been designed using silver and grey shades and simple, sharp and clean lines which run around the entire building. These lines also penetrate the interior of the building where a colorful logo design is used. The logo is placed on a blue area on the floor in the entrance hall and on the under ceiling of the staircase. The interior radiates pleasant light thanks to multi-colored floor designs used in offices.

This has created a very compact, visually clean object, firmly and naturally anchored into the Polabí region. This is meant literary. The building is supported by 56 steel reinforced concrete columns and it is connected to twelve 125 m deep boreholes through which water circulates. Therefore, the building is connected to the ground not only statically but also through the so-called "energy concept".

Fig. The staircase and the lift run through the communication centre of the building, which is fitted with glass panels and illuminated from all sides. Two outdoor terraces hidden behind the company logo on the façade are connected to the floor.

Energy concept

The energy concept is another unique specialty of the building. The project has maximized effective energy management. Teco is not only the investor but also the operator of the building, so naturally, there was a common interest to find an optimum solution between investment and operating costs. For example, the calculation for higher cost of ground drilling also included reduced cost for archaeological survey, which would have been higher if shallow earth collectors were used. In addition to the obvious need for thermal insulation of the building sheathing, low-temperature floor heating system and ceiling cooling systems were selected. Therefore, this concept allowed us to avoid using any air-conditioning units inside the building.

In winter, 10 °C warm water comes from the deep earth boreholes. A plate heat exchanger transmits the heat to the heating circuit, where two PZP heat pumps increase the temperature in the accumulation tank by approximately 13°C reaching the final temperature of 23 °C. From here the heat energy is distributed via control valves to individual rooms and in line with the actual settings. Based on the actual needs the pumps switch to a higher temperature setting and heat up the service water storage tank to approximately 50 °C.

Fig. Heating and cooling circuits before insulations; two heat pumps, two large accumulation tanks, air compressor, central recuperation unit and two wide fields of the control system cabinets and high-voltage circuits were placed in the energy-centre (energocentre); source: Teco, a. s.

In the summer, the water also comes from the boreholes at 10 °C, but this time it is considered “cold”. Through the control valve the water goes to the ceiling cooling system in individual rooms or to the fan-coil units, if no under ceiling are designed in the given room. The cold water cools the interior of the room and then goes back to the 125 m deep boreholes to cool down again. In doing so the water thermally “revives” the boreholes so that the basic heat may be used again during the upcoming winter. To achieve further energy savings, a ventilation system made by Atrea equipped with central recovery unit has been installed throughout the entire building. During winter this system returns the heat back to the ventilated area and vise versa - it returns the cold during the summer. Further in winter, the system also uses the heat generated by the servers and by the SMD component soldering technology. The actual measurement and control of this heating and cooling system is fully handled by Tecomat Foxtrot made by Teco a. s.

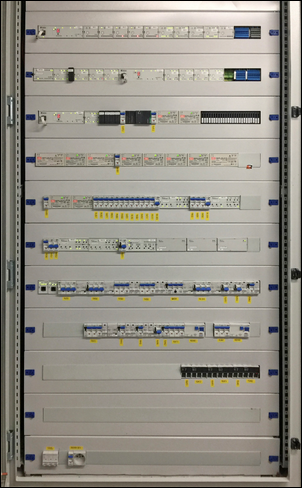

Fig. Complete Tecomat Foxtrot control system including power circuits and

online power consumption measurement in the main cabinet in the energocentre;

source: Teco, a. s.

Rainwater management

Below the building there are six rainwater tanks with a total volume of 100 m3. The water from here is used throughout the entire year to flush toilets and in the summer, it goes to the irrigation system in the garden around the building. Only water supplied to regular faucets and showers comes from the public water distribution system.

Electric power and electric wiring

The new Teco building uses only electricity. No combustion process is used for heating or cooling! All electricity comes from a 150 kW transformer station. Electricity is mainly used for heating, cooling and ventilation and it also powers heat and circulation pumps and fans. It also powers the typical systems. Only LED lights are used for illumination. Even in the public lighting posts around the facility. Electricity also powers computer technology and the newly acquired production technologies used for electronic components soldering, mechanical machining and for laser inscriptions which are used to burn text on plastic parts. The installation of photovoltaic panels and battery storage was not done during the first implementation phase but it will be done in the next phase. Electrical wiring and installation is fully controlled by Tecomat Foxtrot. All high and low voltage systems share data connection. Sockets, switches, blinds and thermostats are connected to more than twenty branches on the CIB installation bus.

Control relay modules together with circuit breakers and protectors in secondary cabinets are located in each of the four sections of the building. Tecomat Foxtrot also offers a connection to the access system and a security switchboard in the building. The security switchboard is connected to the central securty desk. There is also a camera system monitoring the outdoor area. The building has been programmed according to the initial project requirements and ready for any future operational changes and according to various combinations including logical conditions and measured data, for example energy consumption.

And what the company that handled the electrical installation says about the project?

We have asked Radek Červený from ELEKTRIKABRNO s.r.o. which handled the electrical installation directly.

"At the beginning of the last year, I was offered a participation in a tender focusing on electrical installation including Foxtrot control system into a new manufacturing plant of Teco a.s. Because we are the integrator of the Foxtrot system, and we have built a great personal relationship with the manufacturer over the years, the offer for the installation pleased me a lot.

Finally, we were selected to supply a part of the control and MaR system. The fact that the construction project was planned for eight months only, and of course there were various delays, was not a good thing because it created several complications during the implementation process, sometimes even very complex problems I must say, but thanks to our common interest and personal relationship we have managed to solve everything to the satisfaction of all involved parties.

The overall management of the project was prepared by Tecont and even though the project showed signs of a bit different approach than we are used to, I must say that I liked the overall design and the detailed implementation documentation. As expected, the designer included all the technologies in the building and entrusted their control to the superior Foxtrot system. I do not want to list what Foxtrot is controlling here, but I was also interested in one thing. A waste heat is produced during soldering applications, which would be wasted without any benefits. Here, even this detail was addressed and the waste heat is used to help the system to heat up the water in the energocentre.

I would like to stop here for a minute and talk about the energocentre in the new Teco building. It is practically the only room dedicated to machine parts and technologies used in the entire building.

In the original project the energocentre was designed with smaller dimensions but they were increased during the construction to make sure that all the technologies actually fit in this room. It finally turned out that even the increased spaces are still rather tight for all the technology, but there was no additional space available and the location of each component in this room had to be carefully thought out and coordinated with all professions. Even so, it was not easy to go through all the piping, fittings and air-conditioning ducts with the cables of the connected technologies to make sure that the cables are installed within a reasonable distances and look presentable at the same time. The limited space of the energocentre also surprised us just before the final building permit inspection where many professions gathered in such a small space, each claiming completion of their job as the priority, which occasionally, created comic situations. Moreover, during the installation there was a need to manufacture distribution cabinets with control system combined with power components. The supplier of the wiring installation did not have that much experience with such cabinets so he needed to find a way how to solve it. We have offered a non-standard solution and installed the part with the control system. The power part was completed later by the power supplier. This was done successfully thanks to great coordination between all involved parties. Although it was difficult at first to explain why we want to bring the cabinets to the production plant in Brno and why we do not want to bring all the workshop equipment needed for the manufacture of these cabinets, including the equipment that performs the inscriptions on terminals and conductors to Kolín, but eventually everything went well. Finally, I have to evaluate the entire event from the perspective of ELEKTRIKABRNO s.r.o. as a very successful project and I appreciate the personal approach of all the people involved in this event where the coordination of the technological professions was overseen by the investor alone - Teco. The construction was very specific and many milestones which had to be addressed operatively during the construction process but thanks to above-standard approach of all people and companies involved I must say that the entire construction project was a great success.

In conclusion I should point out that the new building of Teco, a.s. also serves as a reference project for the installation of Tecomat Foxtrot system where all interested investors, developers, architects, designers or representatives of universities or colleges are now invited to see on their own and to evaluate the actual functionalities offered by smart industrial buildings - all under full operation.